Expensive Little Boat

Expletive Little Boat

(You get the idea...)

The ELB (Extremely Light Boat) project began as many great ideas do: with a couple of guys messing about with a boat. In this case, my friend Don and his buddy Fred were chatting about how it should be possible to make a very efficient powerboat by using some of the technology that makes a sailboat go fast.

Don and another friend, Mike, decided to quit chatting and take action, and in a couple of hours they had removed the amas from Don's Multi 23 trimaran, built a deck to span them, and created a brand new boat: the design prototype for the ELB. Don's comment on the design at the time was, "With a 2 hp Honda we made 7.7 mph speed and about 70 mpg. Next prototype should be less crude."

The boat is obviously squatting badly and the bows are in the air, sacrificing waterline length. A sailboat does not need a lot of buoyancy aft like a powerboat does, especially one with outboard power. Luckily, Don's son got hold of him at this point and explained that if he really wanted powerboat hulls, borrowing them from any sailboat was not going to work well, and he should have a proper design done. Don's buddy Fred used AutoCAD 3D to loft the hull sections. It is his rendering in Don's imagination in the picture at the top right.

They had a hull shape drawn and created the form over which the hulls would be created and before too long Mike's cow barn was filled with corecell foam dust as they made and glued up strips of structural foam core. This core will have carbon fiber cloth laid over it and then epoxy infused through vacuum bagging to create strong, lightweight hulls. Because it was born in a cow barn, the ELB is sometimes called by the nickname Cowmaran.

The foam strips cover almost the entire form near the bow but steps down to the much lower transom height in stages along the form. Eventually it will be trimmed to a graceful line. The transoms require a bit of extra structure to accommodate twin engines.

After the corecell strips were glued together the seams were faired to create one smooth foam core, ready for carbon fiber cloth and epoxy. The bow is another area that, like the transom, can not be built like the rest of the boat. Although the carbon fiber/foam core construction of the boat is strong, it is also brittle and vulnerable to impact damage, making it an inappropriate choice in the bow.

This is probably the first time this procedure has been done in a cow barn. The hull is completely taped inside the vacuum bag and they are infusing the carbon fiber with epoxy and sucking away any excess. To get the right temperature for the epoxy to cure, they had to construct a little room around large pieces like this one and then heat it with a propane heater. This curing room/oven was made with styrofoam panels and poly tarps.

With the vacuum bag removed, the hull is starting to take shape and look a bit like a race boat in carbon fiber black.

After the exterior surface was vacuum bagged with carbon fiber and the hulls were removed from the form, the insides got the same treatment to form a carbon fiber and foam sandwich structure. Next they constructed carbon fiber and foam bulkheads to support the hulls. As the one in the picture at right shows, each of these was lined with a rim of flexible foam (the yellow stuff). The purpose is to make the joint a bit flexible so as to prevent the stiff bulkheads from "printing" a visible bump through the hulls.

To connect the two halves together, a carbon fiber and corecell foam sandwich deck will ride on four of these 6 inch carbon fiber and epoxy beams. Structural elements like these can really add up in weight and if this boat weighs too much it will either be very slow or it will require a lot of power. These carbon fiber beams each weigh 16 lbs.

The carbon fiber beams tie the hulls together and support the span of the deck set in place. The deck section is one inch thick and weighs only about 100 pounds. Creating a deck and connecting structure weighing only 160 pounds for two 27 foot catamaran hulls is pretty impressive!

Pictured at left is one of the early attempts to fit all of the major structural pieces of the ELB together prior to gluing it all up with epoxy. The rounded spray shield across the front is starting to make it look like a finished boat.

The stern of the ELB after the deck has been glued down onto the structural carbon fiber beams. The transoms are still showing some wrapping from being reinforced.

The splash shield has been covered in carbon fiber in the picture at left. It's all coming together at this point.

One of the nice things about an extremely light boat is that you can stand it on its side to work on it. With pulleys, straps, ropes and comealongs, they were able to easily put the boat in any position desired. The styrofoam that was used to make curing rooms around the pieces came in handy for padding and blocking the boat in place.

Once the structural assembly was done, it was time to turn the boat upside down for painting. Here it is resting on stacks of styrofoam near the beginning of the painting process.

The boat was set back up on its side for some of the painting. I guess doing it from a ladder was easier than trying to avoid walking in wet paint with the boat upside down.

A close look at the picture at left (click to enlarge) shows the various straps and tackle used to lower the boat back down onto a waiting collection of styrofoam pads. The whole boat weighs about 500 lbs at this point, with the beams and deck adding up to around 160 and each hull weighing about the same amount.

Although the structure is not quite finished, the completion of the underside had them thinking about putting it in the water for a test run. Other practical thoughts started to come up, such as exactly where the seats and console should go. At right is an early attempt at modeling solutions to this problem.

The lack of a console or seats was not enough to stop a test run. In this stripped-down configuration, the ELB with 9.8 hp Tohatsu weighs around 600 pounds and was able to achieve about 16 knots.

Meanwhile, the console was being fabricated back in the cow barn using the same structure as the boat: corecell foam core with vacuum bagged carbon fiber infused with epoxy. At right is a front view with the forward bench seat in place and the front side covered in carbon fiber. The front side is angled to reduce wind resistance and provides a comfortable back rest angle.

As the console core was being assembled and encapsulated in carbon fiber, work on the helmsman's bench was begun. The console helm station and bench are very tall, making for great visibility when driving the boat or riding on the bench as a passenger.

After two summers in the making the Cowmaran finally emerged from the cow barn in nearly completed form, complete with console and helm bench. It is on the way down to Florida for final assembly and testing over the winter.

The hulls look nice with a very fine entry and plenty of bridgedeck clearance. It is sitting on a used snowmobile trailer that was bought for the purpose of transporting it to Florida. I still had never seen the boat in person, but had been following the build in Facebook. I was excited to hear that Don planned to bring it out to my yard to do a little work on it before putting it on his lift over in Punta Gorda.

Snowbirds were not the only ones heading South to Punta Gorda in early November. Racers in the Sun Cat National Championship Regatta were also converging on our place for our annual race. The one participant in the concurrent Horizon Cat Nationals said that he saw this strange white catamaran being towed by a small white passenger car several times during his trip down from South Carolina, and he was somehow not surprised when he arrived at my place to find the strange boat here!

In the picture at right, the Cowmaran has a new Com Pac Sun Cat owned by soon-to-be-National Champion Scott to the left and an old Sun Cat of the original production from the 1960s on the right. Any Sun Cat will do. As Head Jib Trimmer In Charge of the Sun Cat Class, I have decided that the class rule is: you must sail a hull that is arguably a Sun Cat hull. Anything else goes.

Sun Cat racer Don came to our regatta welcoming party on his motorcycle and parked it over by the Cowmaran. The two make quite a picture!

While I was distracted by the ongoing Whale Swimming Boat Rebuild, I came over when I saw activity on the ELB to take a picture now and then. They had a nice, high aluminum railing made to wrap all the way around the boat. The fat part of the gunwale is composed of a three layer sandwich of carbon fiber and foam and Don devised clamps to secure the stanchion bases to that part of the boat without causing cracks. In the picture at right, Mike is installing the engine remote control box and the steering wheel in the console.

Because the 9.8 hp is an engine that is used almost exclusively in tiller steering applications, it does not have the tube built into the mounting bracket for a standard remote steering cable. Instead, the engine end of the cable had to be secured in the old fashioned way, with a bracket attached to the transom. In the photo at left, Don and Mike are working on connecting the end of the steering cable and getting everything positioned so that the engine turns all the way in both directions and there is clearance when tilting it.

My First ELB Ride

Disabled Sailing World Championships

Charlotte Harbor, FL 1/12/12

My first chance to take a ride on the Extremely Light Boat came on January 12th when we went out to watch the IFDS Disabled Sailing World Championships on Charlotte Harbor. Disabled sailors were competing in 2.4 mR, Sonar, and SKUD sailboats that are specially equipped to accommodate the physical limitations of the sailors. Light winds caused them to delay the start of racing in the small boats in the upper harbor, but it picked up as the day went on and there was a nice breeze by the time we were down in the central harbor watching the Sonar fleet around midday.

The Cowmaran was already floating when I arrived and I took a few pictures as Don and I waited for a couple of sailors to join us.

It is a bit hard to tell, but yes, it really is floating. I guess it draws about two inches at the bows. It is easily beachable in that respect, but the hulls are too fragile up there to take much punishment from a beach. We are seeking solutions to that problem that do not add too much weight.

The bows are covered with a plywood and carbon fiber deck that is not yet finished in this picture. Also in the "unfinished" category is the square thing on the port bow deck. That is part of one of the structural beams that tie the amas together and support the deck, and there is a matching one mounted in the port ama at the stern. It's a solid point, but too ugly to stay in my opinion.

The hull draft at the transoms is about the same as at the bows - only a couple of inches. Don estimates the weight at this point at around 1,000 lbs, including engine, battery, fuel, remote controls, and basic safety gear.

The high bridgedeck clearance makes an extra long shaft (25") necessary in this configuration. The addition of the planing fin on the cavitation plate all but eliminated early cavitation problems. Now the propeller will swallow a little air now and then if running at high power in a lot of chop, but otherwise it performs fine. The engine is submerged just beyond the little fin above the cavitation plate, or about 13 inches. This is where the ELB has impressive shallow draft: at rest. High tech flats boats can run in very little water using jack plates, low water pickups, and surface piercing propellers, as long as they are planing. The point of a flats boat is to stop in the shallow water and fish, and most have to find a hole to get on and off plane, after which they are down to trolling motors.

By way of comparison, if my 90 hp Yamaha is submerged to the same point, it draws about 19 inches, six more than the engine on the ELB. The difference is mostly in the propeller. The ELB has a prop that measures 8 inches or less, while the prop on the bigger Yamaha is about 14" in diameter. The ELB can go places with the engine fully down that my 15' Boston Whaler can barely go with the engine tilted just because there is a lot more propeller and lower unit to keep in the water.

The moment I have been waiting for all these months as I watched the build from afar! The Extremely Light Boat all rigged and ready for a day on the water. Granted, the rigging and some other aspects are a bit crude at this point, but the boat is still in development. The final plan does not call for throttle and shift cables that cut off access to the helm from one side, but it does work. All of those cords and cables should be concealed in the end, but the boat will go through changes.

A second Tohatsu 9.8 has been ordered, so twin engine controls are going to be needed anyway. The second engine happens to have power tilt, since that was what the dealership had in stock. Power tilt will be incredibly useful for shallow water maneuvering, so I guess the original engine may be upgraded or replaced. One of the nice things about the ELB is that the engines are just not all that expensive by powerboat engine standards, so replacing one is not that big of a deal. Many power catamarans this size have the equivalent of a couple of new cars hanging on the transoms, so you do not just replace one lightly. Depending on the performance with the twin 9.8 hp engines, the boat may wind up with a pair of 15's or 20's. Those engines weigh about 20 pounds more and cost around a thousand dollars more apiece than 9.8's, but still the price for a pair of them could be less than some repair bills on a single V6 outboard.

While we were waiting for a couple of friends to join us, Don showed me a piece they had cut out of the boat during construction. The layer he is peeling off is called peel ply. It's special stuff that will not stick on one side and will allow air to pass on the other side. After the piece is vacuum bagged and cured, it can be peeled off.

The ELB carbon fiber over foam core sample after the peel ply is off, showing the weave of the cloth in the sun. Vacuum bagging helps ensure that the strands of the cloth are soaked but no extra epoxy is left behind.

The ELB has a beam of 8' 6" and it is carried almost the entire length of the boat. The deck spans nearly the entire beam, so it looks like it is almost big enough for a volleyball court. All this space had me really envious. We sometimes set racing marks for sailing races in our 15' Boston Whaler, and a 5' tetrahedron mark in a boat with 5' 3" beam is quite a visual obstacle. We could put three of those marks in the front deck of the Cowmaran and still have room to move around.

Of course, if you have three big marks aboard a boat like this one, at least one or two of them can go on the equally spacious aft deck. I could get a pretty good game of fetch going with our dog on this boat if we just put a net around the railing to catch stray balls.

Don tried to show me the inside of the port ama through this large access hatch, but looking into a black hole in a white deck in the sun is impossible. I learned that if you build a boat in carbon fiber black, painting the insides white would be a good idea. That battery needs to go down in that hole, but there will likely be another battery when there is another engine and their final location is yet to be determined.

The console is very tall and wide, so has a lot of storage space underneath.

When we got out on the harbor, the first stop was the race course being used by the 2.4 mR class in upper Charlotte Harbor near the US 41 bridge. The boats had been floating around becalmed all morning and racing was delayed. When we got there, enough wind was starting to come up that the boats were starting to move around. We decided to head on down to the area off the point of Punta Gorda where the SKUD class was already racing. There was a bit more wind out in that less protected area of the harbor.

As we cruised down the harbor at a little over ten knots with 4 people aboard, the tiny wakes created by the ELB essentially disappeared in the small chop that was developing. This was something new and exciting to me. A powerboat that could go a reasonable speed on very little power, making very little wake. All the powerboats I know make a terrible wake at speeds around ten knots. This one likes to go that speed. We did not even feel the little waves as the bows sliced through them.

We shadowed the SKUD fleet through a couple of races and it seemed to me that the Cowmaran was much better suited to the job than any of the coach boats being used. Almost all of the disabled sailors had a coach boat following along, but the picture at right shows how we saw them from onboard the ELB. If they went fast enough to keep up with the racing sailboats, they would throw a tremendous wake. They were forced to either lag behind or run at high speed well outside the fleet, either of which kind of defeats the purpose of having the coach nearby to watch the race. We could easily outrun the fleet in the Cowmaran, watching the whole fleet round each mark and then running to the next one to beat the first arrival, and we could do it without creating a disruptive wake too near to the fleet.

The same scene played out down in the central part of the harbor when we went down to the Sonar class race course. Coaches in RIBs were either putting along too slowly to keep up with the fleet or fast enough to throw up a wall of water while the ELB was able to shadow the fleet up and down the course. It was a bit choppy out in that part of the harbor by the time we got there, but the ELB is barely affected by waves, especially if taken head-on. Beam seas will rock the boat a bit, of course, but even that motion is fairly muted for such a light boat.

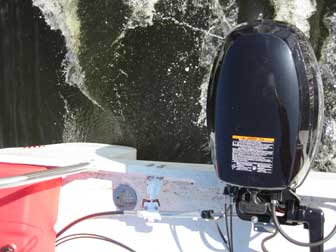

I took a couple of pictures over the stern as we cruised around. The one at right was taken in the canal at a speed of around 5-6 knots.

The picture at left was taken in the harbor at a bit higher speed. I do not think we were going at cruising speed for this one, but probably around 8 knots.

Another Cowmaran Ride

To Nav-A-Gator on the Peace River

In February Don and his wife invited my wife and me to go for another Cowmaran ride, this time up the Peace River to a place called Nav-A-Gator Bar and Grille, where they have a Super Grouper sandwich that is a local favorite. I have never been to the Nav-A-Gator in a car and will never go that way, but am always happy to go there again by boat. It's a necessary part of the Nav-A-Gator experience.

We left from Punta Gorda in mid-morning to allow a little exploration time before lunch. We live on Shell Creek and Don wanted the guided tour of the few ways in and out of Shell Creek and the associated shallow spots. Having hit them all, I'm well qualified to point them out.

In the bottom of Shell Creek we did a little run at full throttle. I'm not sure this was 100% legal. The sign says, "Slow speed, minimum wake." Well, the Cowmaran is slow compared to many powerboats and even its maximum wake is a minimal wake. Anyway, it was a nice, smooth, deserted patch of water, so we opened her up. 12 knots. That's relatively slow, right?

We went on up Shell Creek past the railroad bridge and US 17 bridge and up to the dam. At each intersection along the way, I explained where the various branches led and how they interconnect with one another. They all look pretty much the same at first, and I'm sure much of my explanation did not sink in, but at least now they have seen a couple of the right ways to go and been warned about the worst wrong ones.

When we got back out into the Peace River from Shell Creek, we took the eastern branch of the river, called Hunter Creek. This is a really beautiful waterway that is seldom used. Most people go up and down the main channel, where the speed limit is 25 mph. In Hunter Creek, it is a slow speed, minimum wake zone, which is perfect for the Cowmaran, as discussed above.

We docked at the seawall end, next to the airboat tour operation. There is no place quite like the Nav-A-Gator. It is not just a restaurant. They have a funky little museum, they sell gasoline (ethanol free only), rent slips, give river tours, and have a seaplane dock, just in case you want to visit in your seaplane. They have indoor and outdoor seating and often have live music. It's just a generally fun place, but I would probably seldom come so far up the river if they did not have such a good Super Grouper sandwich.

Another view of our group disembarking at the Nav A Gator lunch dock. They have several docks for use by boaters stopping in for lunch, but only one that is really easy for the Cowmaran to use before the second engine gets here. Making the 90 degree turn into those other docks in the narrow waterway can be a challenge with the single engine.

Sonja and Don chatting at our lunch table on the Nav-A-Gator back porch. It's a NavAGator Afternoon, sit back and enjoy the show, as the Jim Morris song goes...

The side view shows that the lunch docks at Nav-A-Gator generally anticipate that the customers will arrive in boats a bit smaller than 27 feet. This is far from the first big boat I have seen wedged into a little dock here, but it is not all that common.

After lunch we came back down to Punta Gorda Isles via the Peace River and we got as far as the mooring field near the US 41 bridge when we ran out of fuel. We had been running all day on the 3 gallon tank, which started out with only about 2 gallons in it. Don was curious just how long we could go on those two gallons, so we found out. We had plenty of fuel to get home in the 6 gallon tank. I do not know exactly how far we went on those two gallons, but it was a long way. About 8 nautical miles from Don's place to the dam on Shell Creek, at least another 8 up to the Nav A Gator, and about 12 back down to where we ran out of fuel. With a little messing around along the way, we probably went 30 nautical miles on two gallons of fuel.

I will update this page when Don puts another engine on the boat.

Update: The Twin Engine Cowmaran

Some video taken aboard the ELB:

enjoyed the website..have you been out fishing on it any?..seems to be a great platform for almost any water activity…thanks for sharing…

Glad you enjoyed it, Gerald. We have not been fishing on it yet, just development/testing and a few exploration missions. It will make a superior fishing boat for local waters since it draws so little water. I’m helping the owner launch it again today after some upgrades. All those ugly cables on deck have been re-routed underneath the deck and it has new stripes and name graphics on it.